Competence in Rope Access

Competence in Rope Access

Competence (noun) the ability to do something successfully or efficiently.

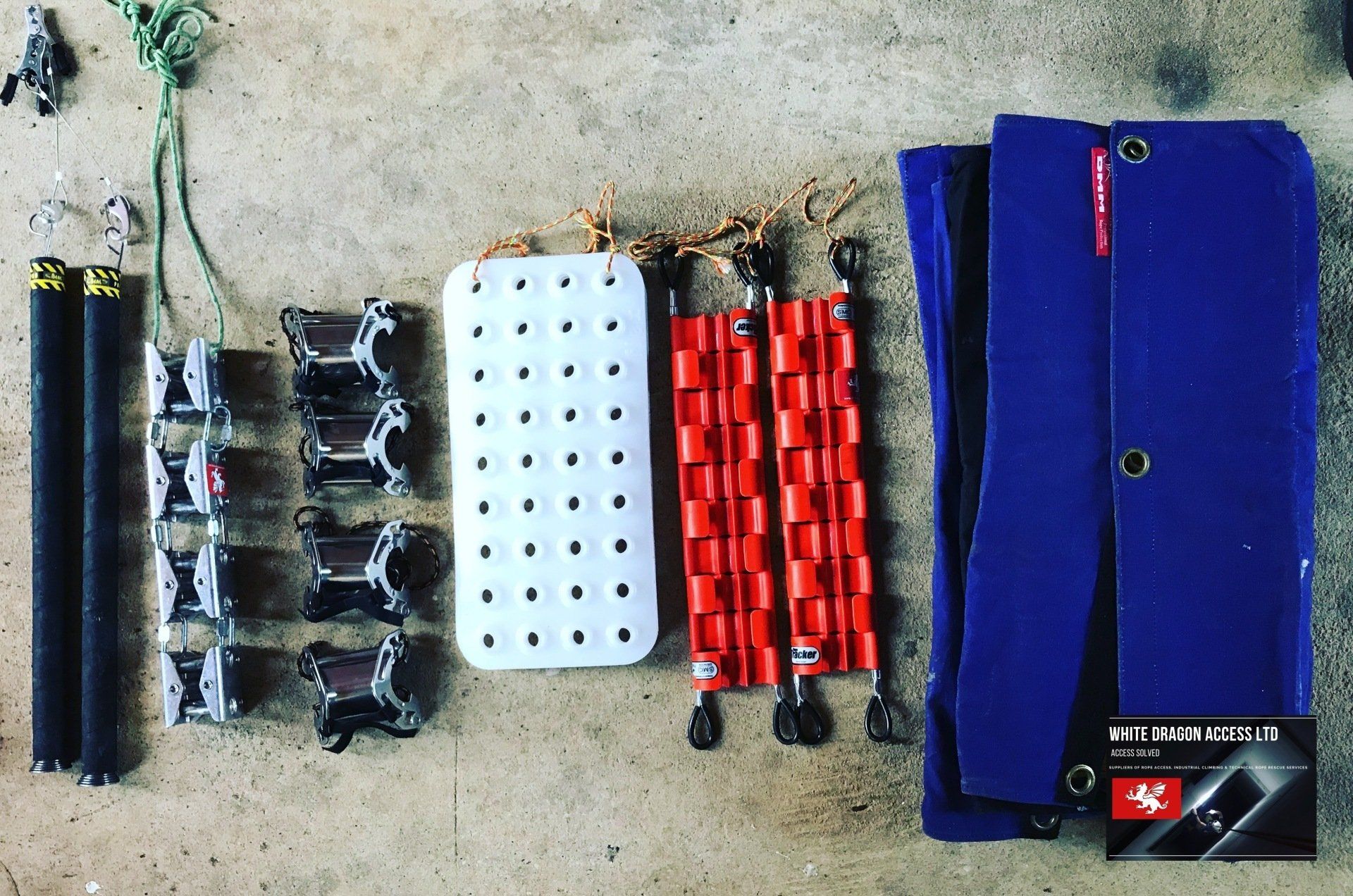

Following on from the last article of "Rope Protection and the Failings" I would like to look at Competence within Rope Access.

Every employer shall ensure that no person engages in any activity, including organisation,planning and supervision, in relation to work at height or work equipment for use in such work unless he is competent to do so or, if being trained, is being supervised by a competent person. (The Work at Height Regulations 2005).

So with that being said, when there is bad/unsafe practice, poor incompetent supervision the law is being broken. The Working at Height Regulations 2005 come under the umbrella of the Health and Safety at Work Act 1974.

Judith Hackitt, HSE’s Chair said:

‘The essence of competence is relevance to the workplace. What matters is that there is a proper focus on both the risks that occur most often and those with serious consequences.

Competence is the ability for every director, manager and worker to recognise the risks in operational activities and then apply the right measures to control and manage those risks.

I would hazard a guess that if you are reading this and are involved in rope access as a technician you are more than likely to have an IRATA certificate. That is not to say that is the only ticket in the UK. BS7985/ISO22846 are also covered in this article.

For those people who have limited or no knowledge of the IRATA Rope Access Certification scheme here's a very quick overview. IRATA training programmes comprise of at least 30 hours training over a minimum of 4 days. At the end of which will be an assessment conducted by an independent assessor (IRATA assessments shall only be carried out by IRATA Assessors who are independent of the candidate, the candidate’s employer and the organisation providing training). There are three levels of certification Level 1 being the beginner if you like, Level 2 intermediate and Level 3 advanced.

Both IRATA and ISO22846 state in regards to competence as the following: Rope access work can only be carried out in a reliably safe manner where people are competent. To be considered competent, a rope access technician needs to have sufficient professional or technical training, knowledge, actual experience and authority to enable them to:

1. carry out their assigned duties at the level of responsibility allocated to them;

2. understand potential hazards related to the work under consideration and be able to carry out appropriate workmate rescue procedures;

3. detect technical defects or omissions in their work and equipment, recognize implications for health and safety caused by such defects or omissions, and be able to specify a remedial action to mitigate those implications.

And both also state: Rope access technicians should have adequate skill and experience to:

1. understand the limitations of their level of training with regard to work practices;

2. understand the various uses of the equipment they use and its limitations;

3. select equipment correctly;

4. use the equipment properly;

5. inspect their equipment;

6. maintain and store the equipment they use.

So we clearly have the guidance to work Safely & Competently. We have been trained and deemed competent by independent assessors. So why are there still failings?

I think we have to look at failure, there are two types of human failure

- Human error is an unintentional action or decision.

- Violations are intentional failures – deliberately doing the wrong thing

If we look at Human error, It can happen to even the most experienced and well-trained person. But violations on the other hand are intentional failures – ‘deliberately doing the wrong thing’. The violation of health and safety rules or procedures is one of the biggest causes of accidents and injuries at work.

Typical causes of violations include:

- workers thinking rules don’t apply to them;

- being under time pressure;

- not having enough workers to do the work;

- not having the right equipment;

- a lack of understanding (Competence)

- perceptions that rules are too strict or unnecessary – ie the perceived benefits outweigh the perceived penalties;

- wanting to take the easy option;

- perception that they won’t get caught;

- peer pressure.

I was recently looking at a tender document and was astounded to see that the weighting would be towards how cheap they could get it compared to the actual quality. In this instance I decided not to go any further with the tender. Does this explain why the same poor standards are seen on work sites again and again, when cost comes over quality? The saying "If you think it's expensive to hire a professional to do the job, wait until you hire an amateur" springs to mind.

I, like most use social media as an advertising platform. I don't post for likes or to get more followers (of course it is fantastic when you get appreciated by others in your field, who doesn't welcome that!), I post because what we do is safe, competent and professional and I like to share that fact. Whilst using social media I see a lot of unsafe acts, which if we look at that statement again from the Working at Height Regulations 2005 is a disregard for the law. I often say "Would they rig like that on their assessment?".

We have all done things in the past where when we look back we think "Yeah that was a bit sketchy" But I feel it's how we learn from our past mistakes and strive to be better is what counts. To have presence of mind and be open to criticism and advice from others. I have found that having mentors who uphold the principals, morals and ethics of a safe work culture invaluable both in the development of my company but also individually as a technician.

Competence regards us all, whether Level 1, 2 or 3, Rope Access Manager or Company owner. Are you competent in management skills or competent in supervisory skills, I think you have to be honest with yourself and if you have failings, address them.

To work as a Rope Access technician is a fantastic and rewarding job, but take pride in what you do. Treat everyday as assessment day. Take your time, prepare it right. Think of the Five P's! Planning Prevents Piss Poor Performance!

Remember a competent person is not someone who simply has the competence to carry out a particular task, It is someone who has the necessary skills, experience and knowledge to manage health and safety.