Unquestionable Anchors, Questionable?

Unquestionable Anchors, Questionable?

We will all be familiar with the term "an unquestionable anchor" but do we all fully understand?

Solid anchor points are fundamental to safe working at height, You can have the best equipment on the market, but this will do you no good if it is ultimately attached to a loose rusty handrail or fall arrest post!

Load or Pull testing each and every potential anchor point is impractical, therefore the majority of decisions made about what is safe are based on experience and common sense.

What is meant by "unquestionable"? Who determines whether it is unquestionable and what does the law and association say?

Definition - Unquestionable: not able to be disputed or doubted

One of the first factors to be considered is the load that the anchor point is intended to take. Even one persons bodyweight can exert a wide range of forces depending on the intended use, equipment used and setup of the anchorage system.

During a site survey as a supervisor, this should be high on your list of things to look at. What do we have in the way of anchors? Have you properly assessed them? Can you observe where they are attached to the sub structure?

How and where we attach to the anchor can affect the strength. Tying to the base of the anchor will reduce the leverage on the anchor.

So what does IRATA say?

IRATA ICOP 2.7.9.2 "..... Anchors and anchorages "should" be unquestionably reliable."

IRATA states that the static strength of an anchor (with the exception of some deviation anchors) should be at least 15kN (1.5 tonne). They arrive at this figure by implementing a safety factor of 2.5. The maximum impact load on the user (force applied to the body) in the event of a fall should not exceed 6kN. (IRATA ICOP 2.11.2.6)

As above, IRATA informs us that anchors should be of an adequate strength, bearing in mind the mass of the user including any equipment worn or carried (IRATA ICOP 2.7.9.5)

Ok so we have “unquestionably reliable” we have “15kN” and we have “should be of an adequate strength” but as an IRATA Level 3 How do we know??

I believe the answer lies in a little document called the TACS or to give its full title “TRAINING, ASSESSMENT AND CERTIFICATION SCHEME “ It states:

Rope access operations utilise a variety of anchors, from purpose-engineered steelwork and eye bolts to temporary ground anchors, weight-boxes and natural anchors such as trees. Rope access technicians with the responsibility for selecting anchors should ensure they are competent to do so. Further Training may be necessary. (IRATA TACS 6.4.2.1)

Both BS7985 and ISO 22846 part 2 reiterate the above. Anchors should: be unquestionably reliable (ISO22846 - 7.7.3.5 )

...... A single element of a structure, (e.g. structural steelwork), a natural geological feature or a tree might have adequate strength to provide a place for anchor points for both the working line and safety line. This should be verified by a "competent" person.(BS7985 - 12.3.1.3)

What do we mean by 'Competent Person"? A competent person is someone who possesses the necessary knowledge, training, and experience to assess, choose, and verify suitable anchor points for rope access work. Their expertise ensures the safety and effectiveness of the system, while complying with industry standards and regulations.

A competent person in this case might be a structural engineer. They perform several types of calculations to determine the strength and safety of a structure. These calculations depend on the type of structure (building, bridge, etc.) and materials used.

To determine what forces the structure must support, such things as dead loads (weight of the structure itself), live loads (Temporary or movable loads ie people) and Environmental loads (wind and snow loadings) will be considered.

“If you are in doubt in regards to the strength of an anchor then you should consult a competent person”.

I would suggest doing your homework before employing or seeking help from some of the people and companies that "claim" to be expert consultants, Just recently I was involved in a work scope where a third party was drawn in to carry out some testing and inspections. I won't go into details but lets just say "Piss Poor".

Whilst writing this I thought it wise and beneficial to not only rely on the standards and codes of practices, but to speak to Level 3s from numerous sectors and differing experience levels. Real world answers to a question that should be easy to answer...

So as an IRATA level 3 are we “competent” to decide what is and isn't unquestionable?

IRATA provides essential and quality foundational training/instruction (in some centres!!) With anchors within a controlled training environment being mainly engineered or professionally installed, but having the competence in identifying unquestionable anchors in the field is tied up in other factors and should be supported with additional training, operational experience and critical decision making skills, which can be learnt over time.

I asked several connections for their opinion and interpretation to the question of having the competence to decide what is and isn't unquestionable. The majority believed that with the experience and knowledge that they had built up, they were comfortable in making this decision.

In my opinion, For me, I am comfortable in deciding whether or not an anchor is unquestionable. If strength is becoming an issue, then common sense would dictate that it's probably not strong enough. Experience and further learning through courses, work shops and having a great group of mentors has aided me and others to come to such conclusions.

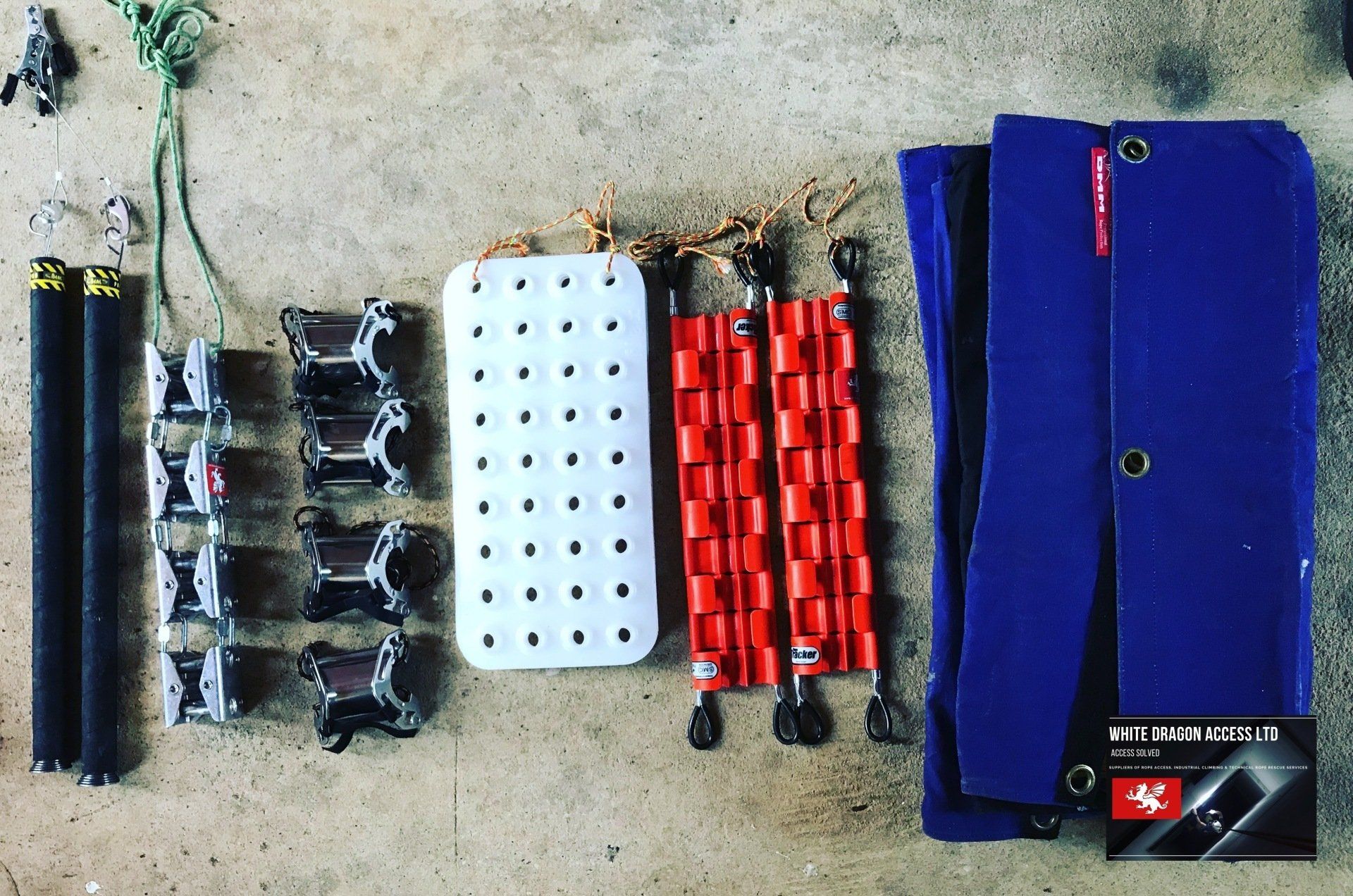

Im not for one instance suggesting within this that all Level 3s should be structural engineers, Nor am I saying that every job requires the consultation of a structural engineer or the like, but they should be competent in the selection of anchors. This also includes the ability to follow procedure and guidelines on equipment. As you will have notably seen from the pictures there is a definite pandemic of mis-use when it comes to anchors but equipment on a whole!

I hope this can start some conversations in regards to competency, equipment use, further training with industry professionals.

Please feel free to comment and share your thoughts, its only by expressing yourself through honesty will things ever change.